CFD Study of Ship Hull

Navtech, a consulting firm in naval architecture and marine engineering, commissioned Lx Sim to conduct a comparative analysis of three ship hull concepts. The objective was to use CFD simulation to evaluate the performance of each design at various speeds and determine the optimal concept before moving into production.

Challenge

- Compare three hull geometries to assess performance at different speeds and identify the best concept prior to manufacturing

Solutions

CFD Simulation

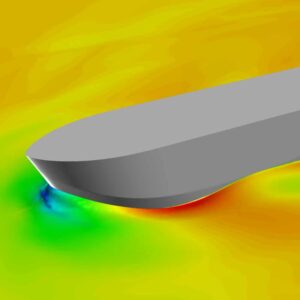

- Modeling of the three ship hulls

- Simulations at five different speeds for each design

- Analysis of drag force, trim, and vertical position of each concept relative to the waterline

Comparative Analyses

- Presentation of results highlighting the advantages and limitations of each concept

- Support in selecting the optimal design based on performance objectives

Results

Thanks to digital simulation:

- Navtech was able to validate its concepts with precision

- The most efficient design was selected before the manufacturing phase

- The client invested directly in a winning solution, reducing uncertainties and costs associated with physical testing

This project illustrates how CFD simulation enables informed and strategic decision-making during the design phase, leading to high-performance outcomes from the start.